Watch It Work

See how manufacturing training becomes visual work instructions and audit-ready SOPs instantly

Shop floor videos can't replace documented work instructions

ISO-Compliant Documentation

Docsie generates SOPs and work instructions that meet ISO 9001, AS9100, and quality management system requirements—with visual steps, safety callouts, and equipment specifications.

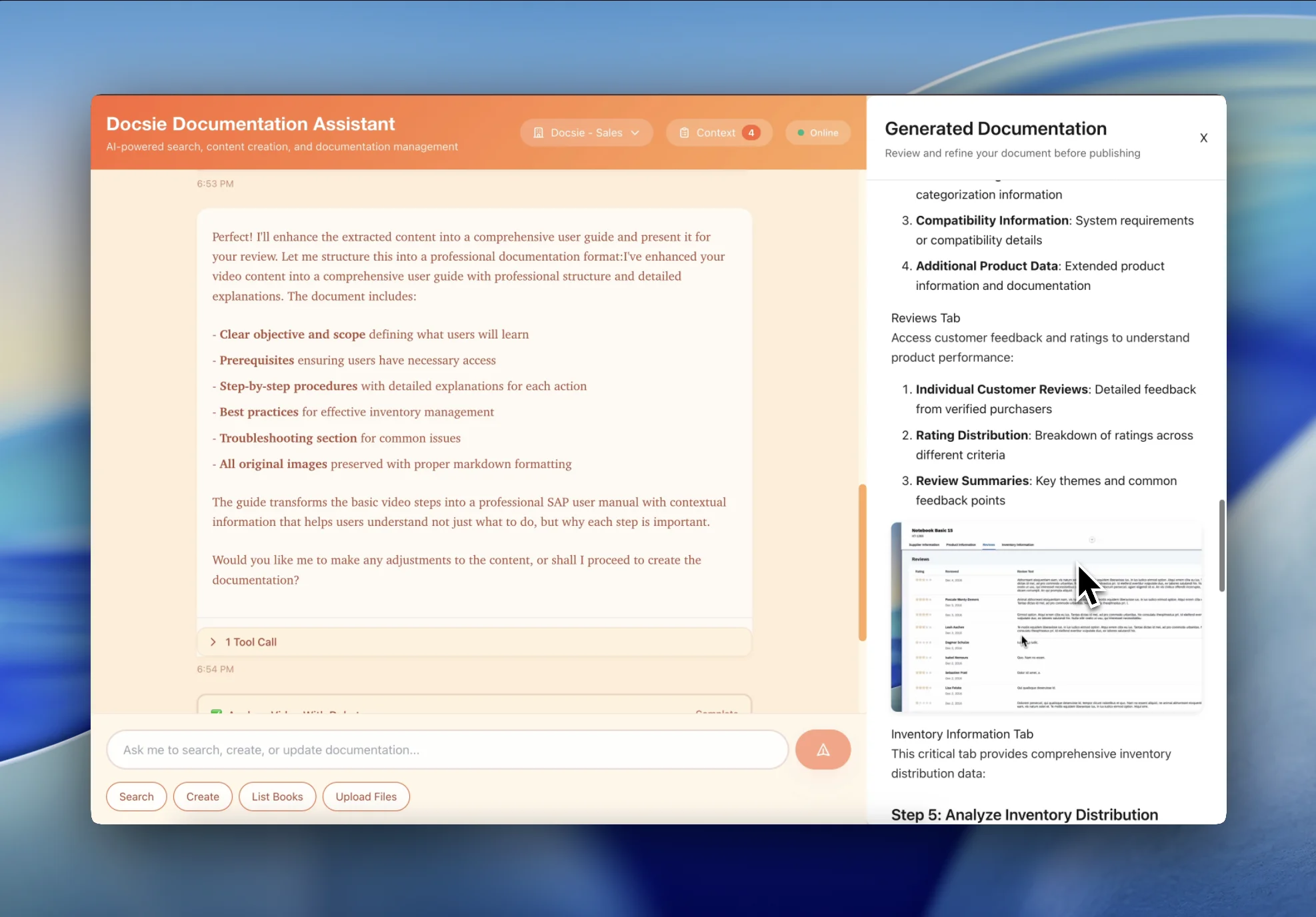

Automatically formats documentation to match ISO 9001/AS9100 requirements—title blocks, revision history, approval workflows, and document control that auditors expect

Extracts equipment setup steps, tool positioning, and assembly sequences as annotated screenshots—perfect for line workers who need visual references during production

Identifies safety callouts, PPE requirements, and hazard warnings from training videos—creates lockout/tagout procedures and safety checklists automatically

Simple Process

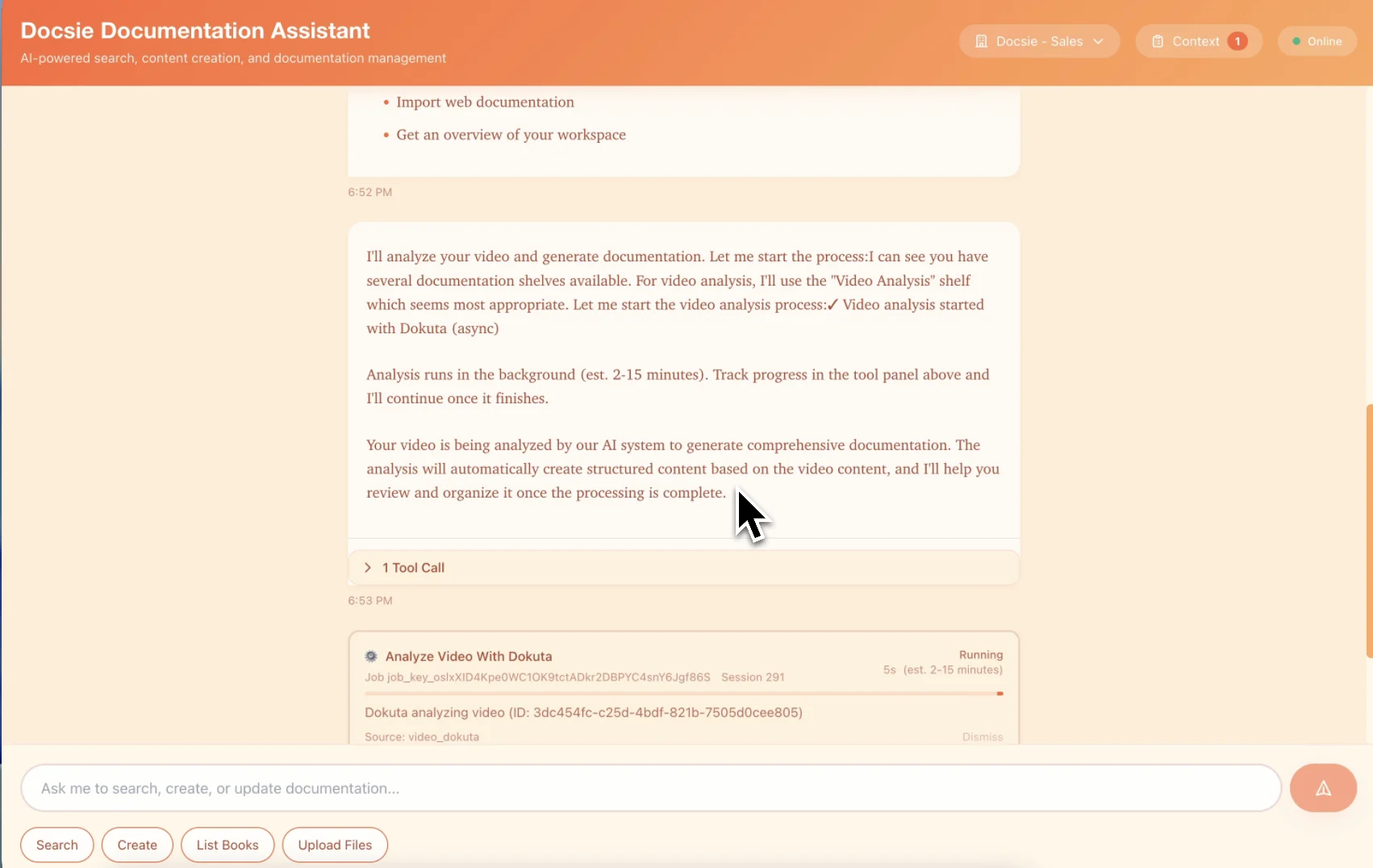

Powered by Docsie Copilot's manufacturing documentation AI

Upload your assembly training, equipment operation, or quality control video. Works with footage from shop floor cameras, tablets, or any recording device

Multimodal AI identifies assembly sequences, tool requirements, safety callouts, and quality checkpoints. Formats into ISO-compliant SOP structure

Get visual work instructions and SOPs with revision history, approval workflows, and document control ready for ISO auditors

See how manufacturers convert training videos into audit-ready documentation

Transform assembly line training videos into step-by-step visual work instructions with tool callouts, torque specifications, and quality checkpoints. Perfect for complex assemblies requiring precise procedures.

Convert CNC, press, and machinery training videos into equipment operation manuals with startup procedures, safety interlocks, and maintenance checklists.

Transform quality control training into inspection procedures with measurement techniques, tolerance specifications, and non-conformance handling.

Audit-ready deliverables from shop floor training footage

Formatted standard operating procedures with title blocks, revision history, and approval workflows

Step-by-step assembly and operation guides with annotated screenshots

Lockout/tagout procedures, PPE requirements, and hazard warnings

Machine setup, calibration procedures, and maintenance checklists

Inspection methods, tolerance specifications, and NCR workflows

Generate documentation in multiple languages for global manufacturing facilities

Watch how Docsie analyzes manufacturing training videos—reading equipment labels, identifying assembly steps, capturing safety procedures—to create ISO-compliant documentation

No credit card required • 14-day free trial

Common Questions

Everything you need to know about converting training videos to SOPs

Q: Does the documentation meet ISO 9001 and AS9100 requirements?

A: Yes. Docsie generates SOPs with all required elements for ISO compliance—title blocks, document control numbers, revision history, approval workflows, and change management. The format matches what quality auditors expect to see during certification audits.

Q: Can we use this for FDA-regulated manufacturing documentation?

A: Yes. Docsie supports audit trails and version control that help meet FDA documentation requirements. The documentation includes timestamp records showing who created and reviewed each SOP—useful for pharmaceutical and medical device manufacturing quality systems.

Q: How do you handle document version control for SOPs?

A: Every SOP includes automatic revision tracking. When you update a training video and regenerate the SOP, Docsie creates a new revision with change history. You can see exactly what changed between versions and maintain an audit trail for ISO compliance.

Q: Can you extract assembly sequences and tool requirements from videos?

A: Yes. Docsie's computer vision identifies tools, parts, and assembly steps shown in training videos. It captures key frames showing hand positions, tool usage, and part orientation—then annotates them as visual work instructions. Perfect for complex assemblies where written instructions aren't enough.

Q: Does it work with overhead camera angles and close-up shots?

A: Absolutely. Our AI handles all camera angles—overhead shots of workbenches, close-ups of assembly details, wide shots of equipment operation, and first-person POV videos. It understands manufacturing context and extracts the right visual moments for work instructions.

Still have questions?

Book a DemoCompatible with shop floor recording equipment and formats

Overhead cameras, workstation cameras, and inspection station footage

Training videos captured on iPads, Android tablets, or smartphones

MP4, AVI, WebM, MOV from any recording device

Start creating professional documentation that your users will love